Apple juice might seem simple, but producing it is a fascinating process. As one of my favorite projects this semester, this hands-on experience gave me valuable insight into the food industry by working on a small batch production of apple juice.

Join me as I take you through the journey of creating this batch and exploring the key stages of the value chain, all through the lens of our course.

Research & Development (R&D): Turning Ideas into Reality

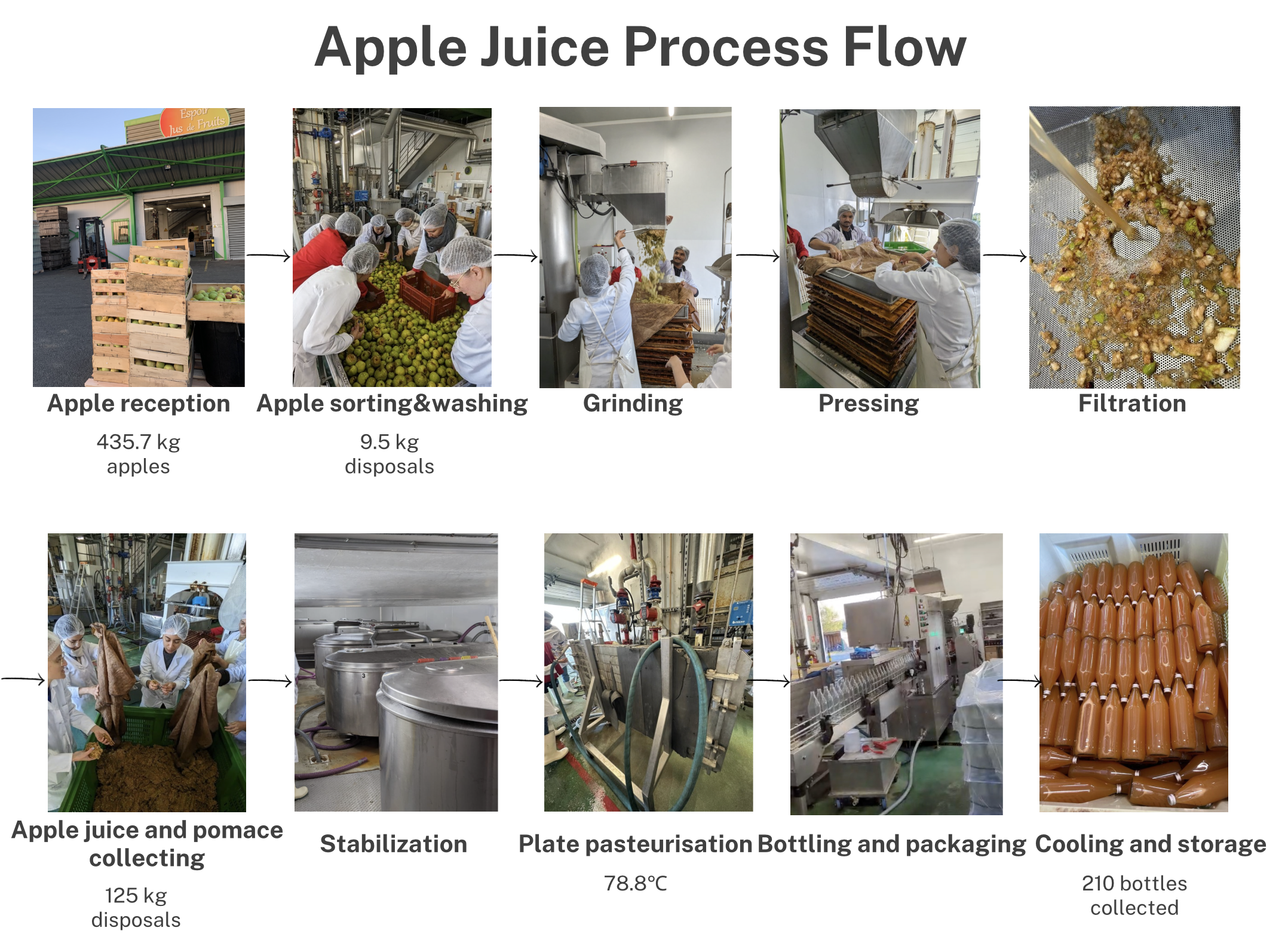

For this project, we skipped the market analysis and consumer behavior studies that typically come before production and went straight into creating a small trial batch of cloudy apple juice. Working alongside my team, we explored the entire process, focusing on key technical aspects like pasteurization temperature and maintaining strict hygiene standards.

Being involved in every step gave me a clearer understanding of the challenges in food processing, from turning on the machines to ensuring the product met quality expectations. This hands-on experience allowed me to see how theory translates into practice on the production floor.

Quality Assurance (QA): Keeping it Safe and Consistent

In the food industry, quality assurance is critical because it ensures that the product meets safety and quality standards, protecting consumers’ health. For this project, we conducted two days of lab work to analyze the physicochemical properties of the apple juice we produced. This included tests for pH levels, sugar content, Total phenolic compounds etc. to guarantee consistency and safety. Working in the lab allowed me to experience firsthand how quality control measures are applied in real-world production.

Sales (SA): Bringing the Product to Market

Once the apple juice was produced and ensured to meet quality standards, it was time to sell! This was my first experience with product branding, and I got to design the label, including the nutritional information and a visually appealing graphic to catch the consumer’s eye. The challenge was not just to make the juice, but to communicate its value to the customer. As we consider the selling period meet the point of Christmas, we created cute blessing card for each bottle with our best wishes :)))

Selling is also a fun but tough part, about how to reach the customer and to get the deals done. We explored different sales channels, from selling in the canteen to setting up stalls at the school marché. We even created a special Christmas campaign, designing festive cards to boost sales during the holiday season. This part of the project offered a simplified yet realistic experience of marketing and selling a product—and we made it! We were sure to sell it all!

Why I learnt go through the bottles of Apple Juice

One of the most rewarding aspects of this project was the opportunity to learn by doing. It was my first time producing something entirely by myself in a factory. As a food science student, I’ve always understood the theory—principles, mechanics, and all—but I had never experienced the practical side of turning on machines and managing the actual production flow. This hands-on experience gave me insights I wouldn’t have gained from books alone, and I felt a strong sense of pride in selling a product I had personally helped to create.

Additionally, this project offered a complete journey through the entire value chain. From collecting raw materials to overseeing production and ultimately selling the final product, I witnessed how each stage plays a crucial role in delivering a product to market. It was a short but intense experience that showed me the importance of every step, from start to finish.